Stellite

- Home

- Stellite

Stellite

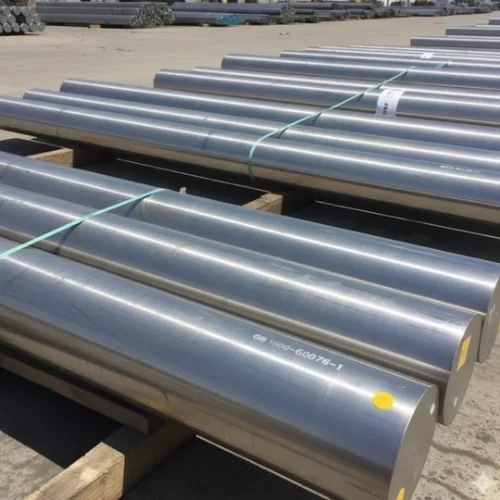

Stellite Alloys are engineered for outstanding wear resistance, galling protection, and durability in demanding industrial environments. These cobalt-chromium superalloys deliver exceptional hardness and strength at elevated temperatures, making them ideal for components exposed to abrasion, friction, and corrosive media. With proven metallurgical stability, Stellite remains a trusted choice across critical applications.

As a leading Supplier and Stockist, Apar Alloys provides Stellite in multiple grades and customized forms to meet diverse engineering needs. Our materials ensure reliable performance in valves, pumps, turbines, cutting tools, and high-wear mechanical components. Every batch is rigorously tested for hardness, corrosion resistance, and durability. With ready stock, global sourcing, and technical expertise, Apar Alloys delivers dependable solutions for heavy-duty industries.

Specifications

| Grade | AISI | UNS | ASTM A276 / A479 | ASTM A182 | EN (W-Nr) | DIN Spec |

|---|---|---|---|---|---|---|

| Stellite 6 | — | R30006 | ASTM B753 | — | — | Stellite 6 |

| Stellite 12 | — | R30012 | ASTM B753 | — | — | Stellite 12 |

| Stellite 21 | — | R30021 | ASTM B753 | — | — | Stellite 21 |

| Stellite 1 | — | R30001 | ASTM B753 | — | — | Stellite 1 |

What Makes Stellite Alloys Unique

Stellite Alloys are known for their exceptional wear and galling resistance, outperforming conventional metals in high-friction and high-temperature environments. Their cobalt-chromium structure, reinforced with tungsten and carbon, delivers remarkable hardness and stability under extreme conditions. Designed for durability and long service life, Stellite remains the preferred choice for applications where reliability and performance are critical.

General Characteristics

Exceptional wear and abrasion resistance

Superior galling and metal-to-metal contact performance

High hardness and mechanical strength

Excellent high-temperature oxidation resistance

Reliable corrosion resistance in acidic and seawater environments

Ideal for hard-facing, cutting, and high-load mechanical applications

Chemical Composition (nominal) %

| Grade | C | Si | Mn | Cr | Mo | Ni | Co | W / Other | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Stellite 6 | 1.0–1.4 | ≤1.20 | ≤1.00 | 27.0–32.0 | ≤1.00 | ≤3.00 | Balance | 4.0–6.0 W | ≤3.00 |

| Stellite 12 | 1.4–1.8 | ≤1.20 | ≤1.00 | 28.0–32.0 | ≤1.50 | ≤3.00 | Balance | 7.0–9.5 W | ≤3.00 |

| Stellite 21 | 0.20–0.30 | ≤1.00 | ≤1.00 | 26.0–30.0 | 5.0–6.0 | ≤3.00 | Balance | — | 2.0–4.0 |

| Stellite 1 | 2.4–3.0 | ≤1.20 | ≤1.00 | 30.0–32.0 | ≤1.00 | ≤3.00 | Balance | 11.0–13.5 W | ≤3.00 |

Applications

Valve seats, valve stems, and wear-critical valve components

Pump sleeves, bushings, bearings, and mechanical seals

Cutting tools, machining inserts, and dies

Turbine blades, compressor components, and aerospace parts

Hard-facing of industrial machinery and high-friction surfaces

Oil & gas, petrochemical, and power-plant equipment exposed to erosion

Advantages

- Long-lasting performance in severe wear conditions

- Exceptional galling resistance without lubrication

- High strength and hardness at elevated temperatures

- Excellent corrosion and oxidation resistance

- Stable mechanical properties across temperature extremes

- Reduced downtime due to extended operational life

Mechanical Properties (Typical at Room Temperature)

| Property | Value |

|---|---|

| Tensile Strength | 700 – 900 MPa |

| Yield Strength | 450 – 600 MPa |

| Elongation | 1 – 5% |

| Hardness | 430–480 HB (≈45–50 HRC) |

| Density | ~8.4 g/cm³ |

| Maximum Service Temperature | 800–1000°C |

Why Choose Apar Alloys

Reliable Supplier & Stockist

Consistent availability of Stellite grades with ready-to-dispatch inventory.

Global Sourcing Network

Materials sourced from reputed international mills to ensure top-grade quality.

Strict Quality Assurance

Each batch undergoes detailed inspection, testing, and complete certification.

Customized Supply Solutions

Available in custom sizes, cuts, shapes, and finishes for project requirements.

Competitive Pricing & Timely Delivery

Cost-effective solutions with guaranteed fast delivery for urgent needs.

Technical Expertise & Support

Professional guidance helping customers choose the right grade for their applications.

Get in Touch

Contact Us

Looking for high-performance Stellite Alloys for your industrial applications? Contact Apar Alloys today for custom sizes, specifications, competitive pricing, and technical assistance. Our team is ready to support your project with premium-quality Stellite materials.

[Call] +91 98333 89128

301, 3rd floor, A WING, Krishvi Escape, Near Vinay Health Home, Fanaswadi Bhuleshwar, Mumbai - 400002.

Send MailContact

Office Address :Apar Alloys,301, 3rd floor, A WING, Krishvi Escape, Near Vinay Health Home, Fanaswadi Bhuleshwar, Mumbai - 400002

Services

- Forging Solutions

- Forged Rings

- Finished Shafts

- Rolled Rings

Join with

3.5 Subscribers

Copyrights 2025 MetalBulls, All Rights Reserved.