Quality

- Home

- Quality

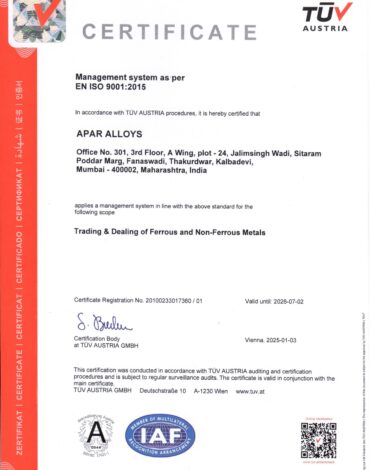

Quality Assurance at Apar Alloys

Precision • Compliance • Traceability

At Apar Alloys, quality is the foundation of everything we do. We understand that the reliability of your projects depends on the integrity of the materials supplied. That is why our quality assurance systems are integrated into every stage—from raw material sourcing to final dispatch.

Our materials are engineered to meet the stringent requirements of critical engineering, pressure vessels, oil & gas, power, petrochemical, and heavy industrial applications, fully complying with ASTM, ASME, ISO, and EN standards.

Material Certification & Full Traceability

All materials supplied by Apar Alloys are accompanied by EN 10204 – 3.1 Material Test Certificates (MTCs) issued by the manufacturer and verified by our quality control team.

Each certificate confirms:

- ›Chemical composition as per applicable ASTM / ASME / EN standards

- ›Mechanical properties including tensile strength, yield strength, elongation, and hardness

- ›Heat number, batch number, and full traceability

This ensures complete transparency, regulatory compliance, and material reliability for end-use applications.

End-to-End Material Traceability

Complete traceability is a core quality objective at Apar Alloys.

- ›Every product is traceable from raw material source to final delivery

- ›Heat numbers are recorded and maintained at every stage of processing

- ›All documents reference heat numbers and batch details

Endorsed Certification Chain

All EN 10204 – 3.1 MTCs supplied by Apar Alloys follow a continuous certification chain:

Manufacturer → Apar Alloys → End Customer

This unbroken documentation flow is essential for audits, exports, and regulated industries.

Approved Sourcing from Reputed Manufacturers

Apar Alloys procures materials only from approved and reputed manufacturers. Each supplier undergoes a strict evaluation process focused on:

- ›Manufacturing process and plant approval

- ›Availability of advanced melting facilities such as LRF / VD

- ›Capability to meet precise customer and industry specifications

Heat Treatment as per Customer & International Standards

Where required, Apar Alloys provides additional heat treatment strictly in accordance with:

- ›Customer-approved procedures

- ›Applicable ASTM / ASME / ISO / EN standards

Our heat treatment scope includes:

Each heat treatment cycle is digitally recorded with time–temperature profiles, soaking duration, and cooling methods.

Solution Annealing

Stress Relieving

Normalizing

Quenching & Tempering

Custom thermal cycles as specified

Documentation & Long-Term Record Retention

Each supply is accompanied by a complete set of quality documents, including:

- ›Mill Test Certificates

- ›UT reports for each line item

- ›NABL laboratory reports (where applicable)

- ›Heat treatment charts

All records are securely maintained for up to 10 years, ensuring easy traceability for audits, repeat orders, and regulatory requirements.

Post Heat Treatment Verification (NABL Accredited)

To ensure complete metallurgical conformity, all heat-treated materials are re-tested at NABL accredited laboratories.

Testing may include:

- Chemical analysis

- Tensile and mechanical testing

- Hardness testing

- Impact testing (Charpy), where applicable

Final Quality Dossier Includes

- Heat treatment charts

- NABL accredited lab test reports

- EN 10204 – 3.1 MTC

- Customer-specific documentation

Comprehensive Testing & Inspection

Every batch supplied by Apar Alloys undergoes rigorous inspection and testing, including:

Sample and heat-wise testing at NABL approved laboratories

100% Ultrasonic Testing (UT)

Positive Material Identification (PMI)

Internal hardness testing using portable hardness testers

Third-Party Inspection & Witness Testing

For high-integrity and export-critical projects, Apar Alloys facilitates Third-Party Inspection (TPI) and witness testing as per customer or project requirements.

We support inspections by:

- › Internationally recognized inspection agencies

- › Customer-nominated inspectors

- ›Stage-wise inspection during testing and heat treatment

All inspection stages are aligned with approved QAP / ITP requirements.

Colour Coding System for Easy Identification

Apar Alloys follows a standardized colour coding system for round bars to ensure quick identification, accuracy, and efficient handling.

This system minimizes errors, improves workflow, and ensures customers receive the correct grade every time.

Material Identification, Marking & Labelling

All materials are physically identified, labelled, and marked in accordance with applicable ASTM / ASME / EN standards and customer specifications.

Marking includes:

- ›Heat number

- ›Material grade and specification

- ›Size and batch details

- ›Apar Alloys identification

This ensures positive material identification (PMI-ready) and eliminates the risk of mix-ups during storage, processing, and installation.

Test Certificate Verification

Every test certificate undergoes a structured verification checklist based on material grade before dispatch.

This process ensures that all chemical, mechanical, and compliance requirements are accurately met.

Sample Test Certificates & Transparency

Apar Alloys provides complete transparency through sample documentation, including:

Manufacturer Mill Test Certificates

Heat Treatment Charts

NABL Approved Lab Reports

Ultrasonic Testing Reports

Records can be easily traced using invoice numbers or customer order references.

The Apar Alloys Quality Advantage

Apar Alloys delivers material integrity you can trust—every time.

Engineered compliance

Complete traceability

Multi-stage inspection

Export & audit ready documentation

Get in Touch

Contact Us

Looking for high-quality alloy materials for your industrial applications? Apar Alloys offers certified grades, custom dimensions, competitive pricing, and expert technical support. We deliver alloy materials engineered to meet strict quality standards, ensuring durability, precision, and consistent performance.

[Call] +91 98333 89128

301, 3rd floor, A WING, Krishvi Escape, Near Vinay Health Home, Fanaswadi Bhuleshwar, Mumbai - 400002.

Send MailContact

Office Address :Apar Alloys,301, 3rd floor, A WING, Krishvi Escape, Near Vinay Health Home, Fanaswadi Bhuleshwar, Mumbai - 400002

Services

- Forging Solutions

- Forged Rings

- Finished Shafts

- Rolled Rings

Join with

3.5 Subscribers

Copyrights 2025 MetalBulls, All Rights Reserved.